The quality department of the company has 12 people, with an average working experience of more than 8 years, with testing equipment such as three coordinates, material hardness, material analysis, strict quality control process and related inspection and testing standards, all process control and engineering control technology, to analyze, solve and prevent quality problems in the production process, to ensure the production of high-quality products.

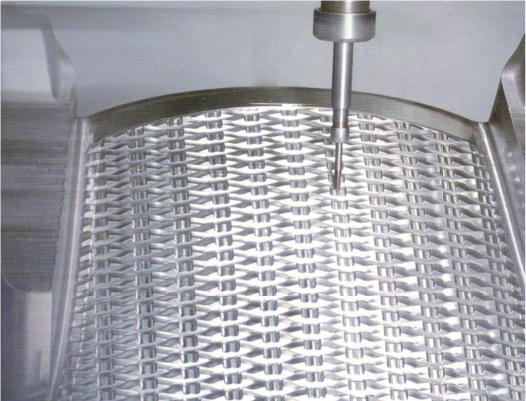

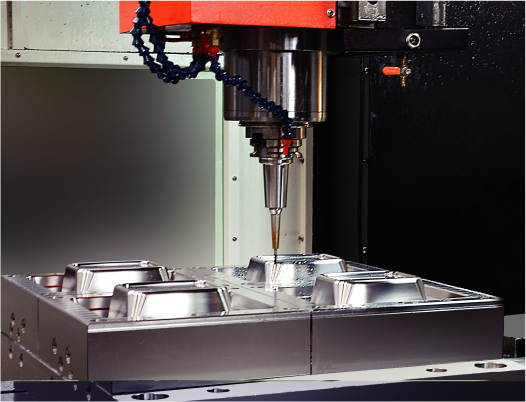

Unionmould use CNC high-speed milling, with five-axis linkage, and spindle rotation is generally 15000-30000r/min. In addition, Unionmould also attach great importance to equipment renewal, equipment depreciation period is generally 4-5 years.Addition of CNC high-speed milling machines is one of the key points of equipment investment in mold enterprises.

Main equipments:5-axis CNC— 1set; 3-axis CNC——7set

shigh speed CNC—7sets

high speed ENGRAVING— 12sets

EDM— 2sets; fitting machines— 3sets

injection machines— 40sets etc.

With advanced equipment, scientific process and experienced staff, we can guarantee to provide customers with high quality molds and products, experienced technicians, advanced machine tools, we are confident that we have the ability to meet or even exceed customer requirements on quality.Advanced equipment gives us the ability to doevery detail.

High-speed, precise, automated processing equipment Effective use of materials with superior quality to create parts that customers trust.High-speed, precise, automated processing equipment Fundamentally guarantee quality and cycle Fundamentally guarantee quality and cycle.